Aluminum Alloy Casting G & M Die Casting

This aluminum die casting guide provides a complete breakdown of this top-notch process, including its advantages and applications.

Die Casting Aluminum Die Casting Alloys Aluminum Casting

Die cast aluminum alloy mainly consists of silicon, copper, magnesium, iron, manganese, and zinc. Each element has a different impact on the properties of the alloy. When working with aluminum, you need to choose which type of aluminum alloy to use in the die casting services.

Special aluminum alloy diecasting anodized colorShenzhen Kasite Precision Technology Co., Ltd.

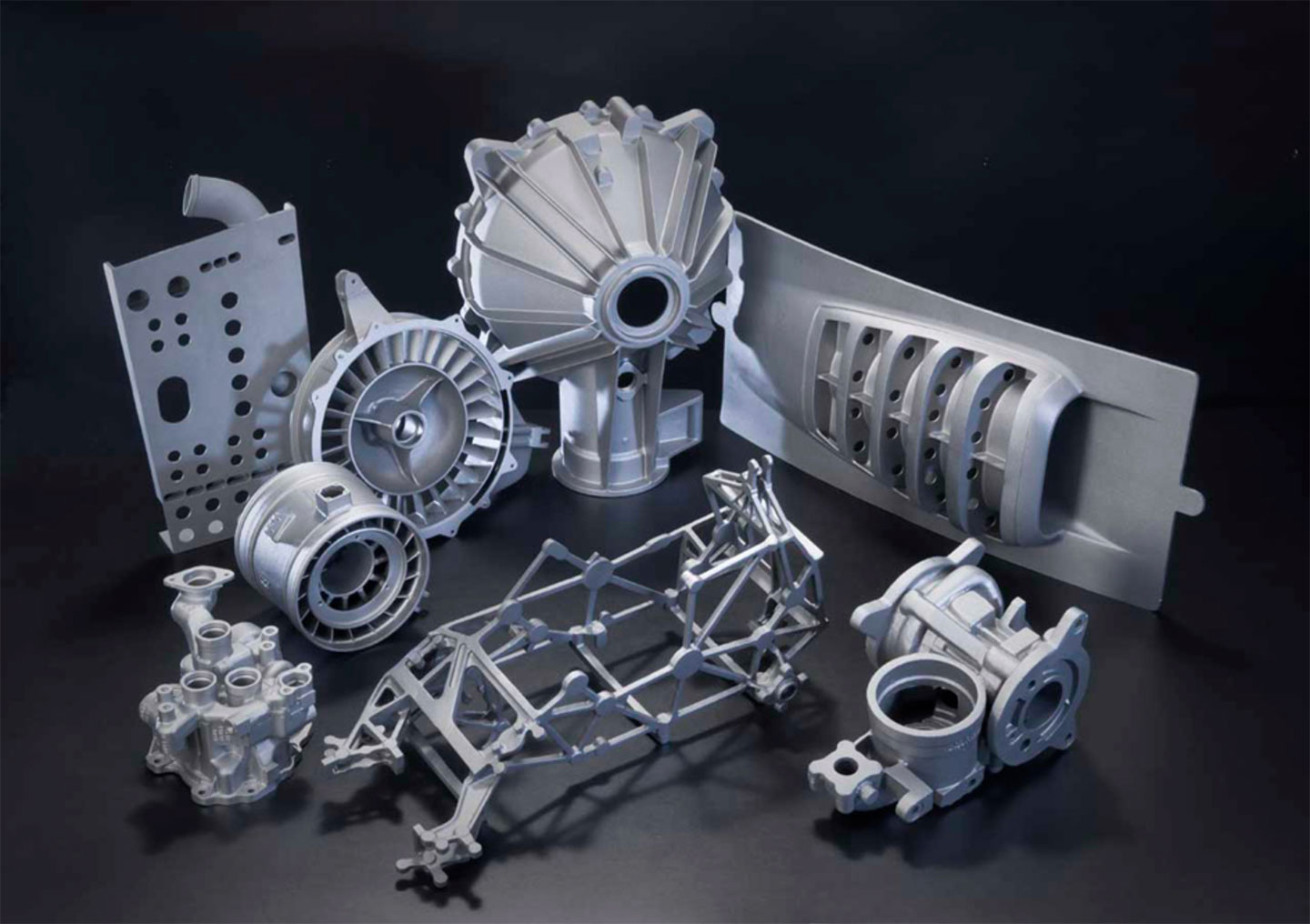

Aluminum castings are lightweight and able to withstand the highest operating temperatures of all die cast alloys. Aluminum Alloy Characteristics: High operating temperatures Outstanding corrosion resistance Lightweight Very good strength and hardness Good stiffness and strength-to-weight ratio Excellent EMI and RFI shielding properties

6 Polishing Methods of Aluminum Alloy Die Casting EMP Tech Co.,Ltd

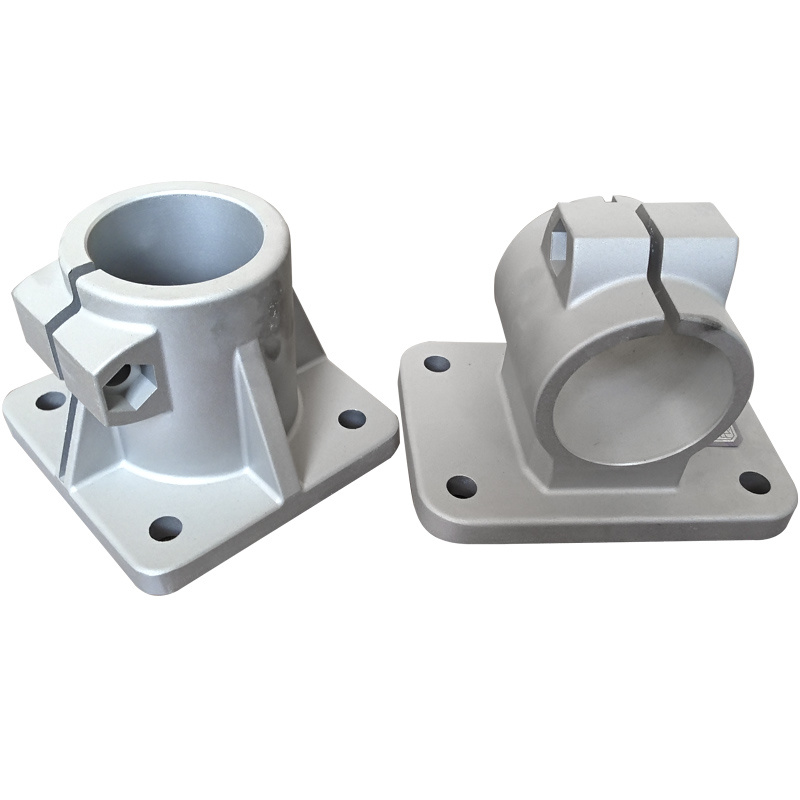

The typical wall thicknesses for aluminum die casting design can range from 0.787 in. (2.0mm) to 0.1737 in. (3.5mm). It also depends on the part's size and structure. But this is subject to change depending on the alloy, part configuration, part size, and application of your die casting parts.

China Aluminum alloy die casting mold and die casting aluminum parts, High Quality Aluminum

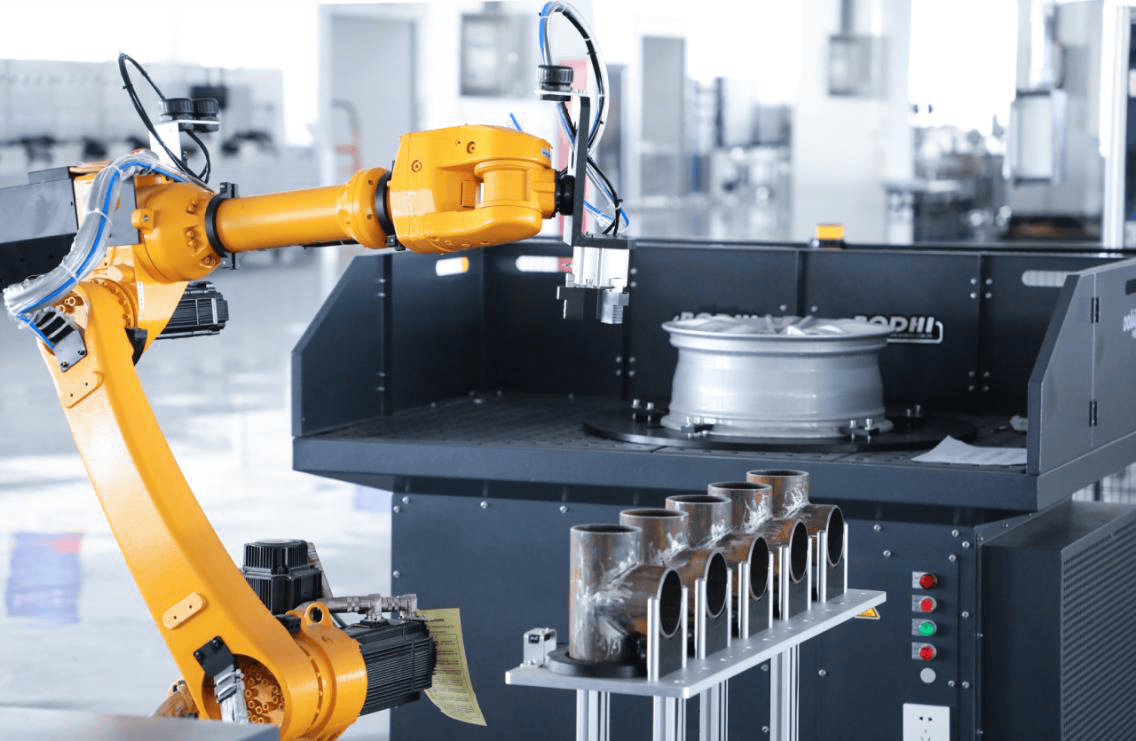

Aluminum die casting is a revolutionary process that has transformed the industrial manufacturing landscape. This method, renowned for its efficiency and versatility, involves forcing molten aluminum under high pressure into a steel mold or die.

Aluminum Die Casting Alloys Which One is the Right Choice?

Aluminum die casting alloys are lightweight and possess high dimensional stability for complex part geometries and thin walls. Aluminum withstands good corrosion resistance and mechanical properties as well as high thermal and electrical conductivity, making it a good alloy for die casting.

Aluminum Alloy Die Castings manufacturer and supplier

DIE CAST METAL PROPERTIES Mechanical Properties Imperial US/UK | Metric Physical Properties Imperial US/UK | Metric Composition Compare different types of die casting metal with this great tool!

Custom Die Casting Aluminum Alloy with High Quality Control EASTEEL

Aluminum is one of the most commonly used materials in die casting but it is just one of the alloys that we offer here at Dynacast. Creating the perfect component begins with choosing the right material and when it comes to making this choice, we don't believe in limiting your options.

Aluminium Alloy Gravity Die Casting at Rs 350/kilogram Aluminium Gravity Die Casting in

Learn about best practices for aluminum die casting design. Here, we provide nine considerations to help improve manufacturability. +1 (603) 749-1995 (USA) [email protected].. Apr 5, 2022 | Aluminum Die Casting, Aluminum Alloys. Once you have decided that the aluminum die casting process is suitable for your project, a crucial next step is.

Aluminum Castings O'Fallon Casting

Material Information Aluminium Aluminium Aluminium castings are lightweight and able to withstand the highest operating temperatures of all die cast alloys. Aluminium alloy characteristics: High operating temperatures Outstanding corrosion resistance Lightweight Very good strength and hardness Good stiffness and strength-to-weight ratio

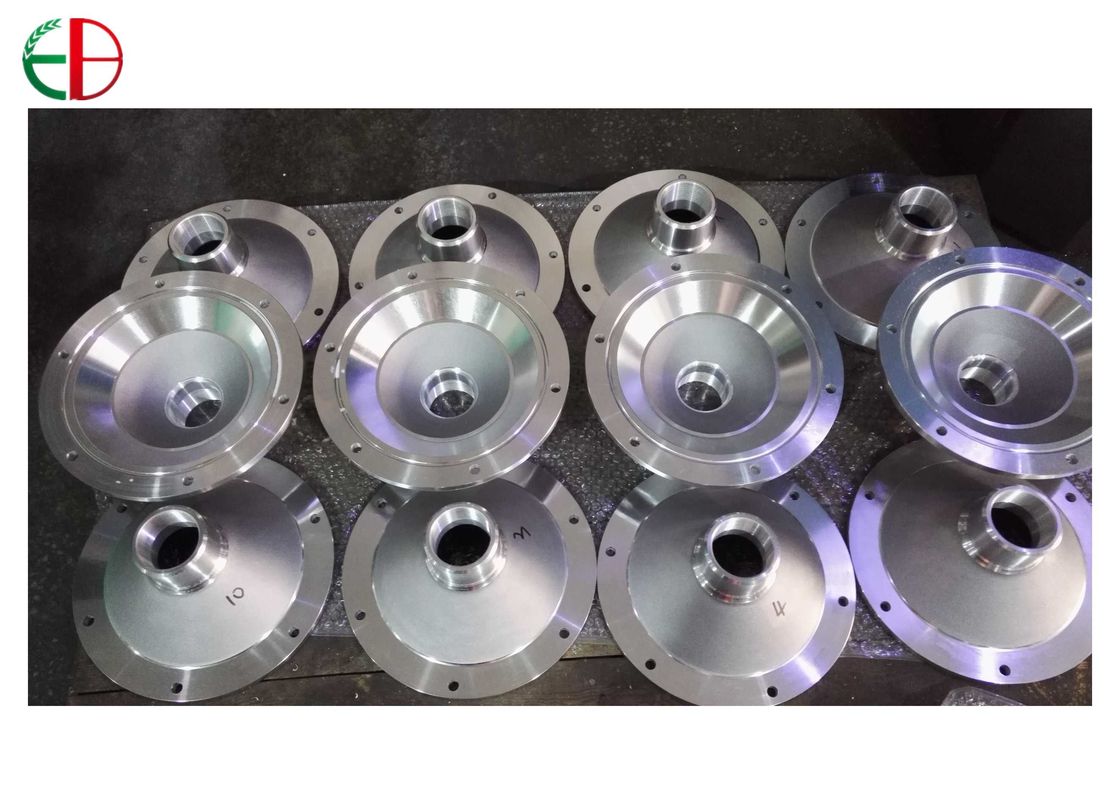

High Precision Aluminum Casting Alloys / Alu Die Casting Parts CNC Machining

Cast metal The main die casting alloys are: zinc, aluminium, magnesium, copper, lead, and tin; although uncommon, ferrous die casting is also possible. [6] Specific die casting alloys include: zinc aluminium; aluminium to, e.g. The Aluminum Association (AA) standards: AA 380, AA 384, AA 386, AA 390; and AZ91D magnesium. [7]

Aluminium Alloy Precision DieCasting with Machining (DR043) China Casting & Products

Aluminum die casting alloys. The specific alloy chosen for a die casting application depends on various factors such as the intended use, required mechanical properties, environmental conditions, cost considerations, and manufacturing requirements. Each alloy has its advantages and is suitable for different applications based on its unique.

Die Casting Aluminum Alloy Elements Best Aluminum Alloys For Die Casting, AlSi Alloys, AlCu

Our aluminum die casting processes accurately produce aesthetically pleasing parts in a wide range of shapes and sizes. Contact us for more information regarding our precision aluminum die casting service options, or call us at 510-523-2541 to speak with an expert. SKS is your trusted source for advanced aluminum die casting services.

Aluminium Alloy Casting Die Cast Aluminum Alloy ALU Die Casting

Hot cracking, also known as solidification cracking, is a typical die casting defect for aluminum alloys that can result in internal or surface-level tears or cracks. This casting defect is generally attributed to thermally-induced internal stress and strain, which form during the solidification process as the cast contracts.

Aluminum Die Casting Machine 1300Ton Yomato Pressure Die Casting Machine

A413. A413 is an aluminum alloy with excellent pressure tightness. This makes it a good choice for hydraulic cylinders. The castability of this aluminum alloy makes it a great choice for die casting intricate components.

Alloys Cast Thompson Aluminum Casting

Alloy A380 (ANSI/AA A380.0) is the most commonly used aluminum die casting alloy, offering the optimal combination of casting, mechanical and thermal properties as well as ease of production. A380 is specified for a wide range of applications, including electronic and communications equipment, automotive components, engine brackets.